Venturi Scrubber System

Venturi Scrubbers

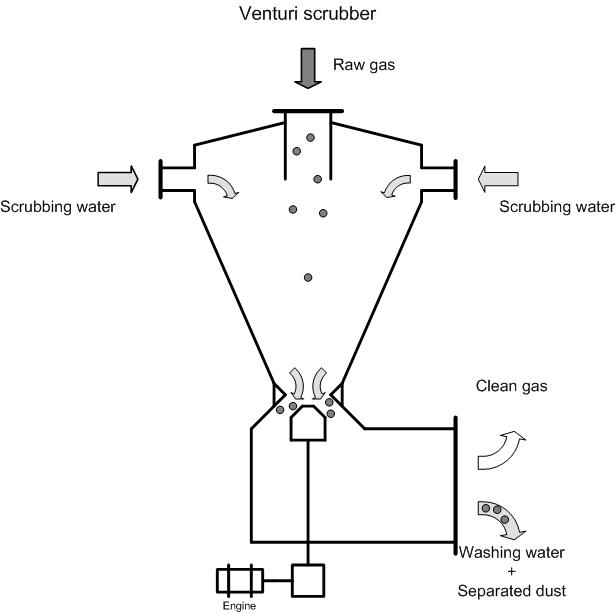

A venturi scrubber is made up of a converging portion, a throat (the venture tube's narrowest section), and a diffuser. The dust/gas mixture moves through the venturi tube at its fastest point in the throat region. After that, the mixture enters the diffuser, where the speed is reduced once more. Either before or during the throat segment, liquid is injected into the gas flow. In the venture tube's throat region, the gas and liquid are well mixed. Water is ejected in tiny water droplets because of the great speed that the gas and liquid can achieve.

A little volume exists within the venturi scrubber itself. The droplet separator, which may be several times larger than the scrubber, plays a major role in determining the installation's size.

Venturi scrubbers can be used to remove tiny particles (less than 1 mm) from a gas stream. However, doing so has an abnormally high energy cost. They can also be used for bigger particles. Even at quite high pressure drops, some types of dust cannot be separated. Some venturis include a variable throat section width, allowing the separator to be adjusted for various flow volumes while retaining a high yield.

What Are Venturi Scrubbers ?

Venturi scrubbers are air pollution control devices that use a Venturi tube to create a high-velocity gas stream, which is then mixed with a liquid spray to remove particulate matter and other pollutants from industrial gas streams.

The principle of operation of a Venturi scrubber is based on the Venturi effect, which is the reduction in fluid pressure that occurs when a fluid flows through a constricted section of a pipe. In a Venturi scrubber, the gas stream containing pollutants enters a constricted section of the scrubber, known as the throat. The gas stream's velocity increases as it passes through the throat, creating a low-pressure zone.

Liquid droplets are injected into the gas stream through nozzles located in the liquid injection section. The high-velocity gas stream mixes with the liquid droplets, causing the pollutants and particulate matter to collide with the liquid droplets. The liquid droplets then capture the pollutants and particulate matter and carry them to the scrubber's mist eliminator section.

The mist eliminator section separates the liquid droplets from the gas stream, allowing the clean gas to exit the scrubber and be released into the atmosphere. The separated liquid droplets collect in a sump, where they are removed from the scrubber.

Venturi scrubbers are used in a wide range of industries, including power generation, chemical manufacturing, and metal processing, to control air pollution emissions. They are effective at removing particulate matter and some gases and vapors but may not be suitable for removing certain types of pollutants, such as volatile organic compounds (VOCs).

How Does a Venturi Scrubber Work?

A Venturi scrubber works by using a Venturi tube to create a high-velocity gas stream, which passes through a liquid spray. The liquid droplets in the spray capture the particulate matter and pollutants in the gas stream, which are then removed from the gas stream. Here are the main steps of how a Venturi scrubber works:

1. Gas stream enters the throat: The gas stream containing the pollutants enters the Venturi scrubber's throat, which is a constricted section of the scrubber.

2. Acceleration of gas stream: The gas stream's velocity increases as it passes through the constricted throat section, creating a low-pressure zone.

3. Liquid injection: A liquid spray is injected into the gas stream through nozzles located in the liquid injection section. The liquid droplets in the spray capture the pollutants and particulate matter.

4. Mixing of gas and liquid: The high-velocity gas stream mixes with the liquid droplets in the liquid spray, causing the pollutants and particulate matter to collide with the liquid droplets.

5. Separation of liquid and gas: The gas stream and liquid droplets then enter the mist eliminator section, which separates the liquid droplets from the gas stream. The separated liquid droplets then collect in a sump, where they are removed.

6. Clean gas exit: The gas stream exits the scrubber and is released into the atmosphere, which is now free from pollutants and particulate matter.

Overall, a Venturi scrubber is an effective air pollution control device that can remove particulate matter and pollutants from industrial gas streams. However, the efficiency of a Venturi scrubber depends on several factors, including the type and size of pollutants, gas flow rate, and liquid-to-gas ratio.

Venturi Scrubber Advantages & Disadvantages

Simple and compact construction

No mechanical components

Gaseous components are absorbed

Able to deal with fluctuating gas flows

No ventilator required

Relatively low maintenance

High removal yield

Signs of erosion when scrubbing abrasive mediums

Difficulty of wet waste disposal.

Potential higher cost.

Large pressure drops

Hot flue gases (up to 1000 °C) are "quenched" using the venturi scrubber as a cooler.

There are many applications for venturi scrubbers, including:

The metal industry for various types of waste gases

The chemical industry, to separate dust and aerosols

Potato-processing industry for the removal of starch

Waste incineration installations

Gasification processes

Melting processes in metallurgy

Glass industry

Sintering processes

Drying processes

Foundries

Pharmaceutical industry

Plastics industry

Fertiliser production.